What Is Paintless Dent Repair and How Does It Work?

Paintless Dent Repair, commonly known as PDR, is a highly skilled method of removing dents and dings from a vehicle’s body without sanding, filling, repainting, or replacing panels. Instead of covering or hiding the damage, PDR restores the metal back to its original shape, preserving the vehicle’s factory paint and structural integrity. This makes PDR one of the most precise, efficient, and valuable services in the auto reconditioning industry. It is a craft that blends technique, patience, and specialized tool control.

PDR is based on understanding how metal moves. Every dent represents a change in the way the metal reflects light, curves across its surface, and holds tension. The purpose of PDR is to reverse that pressure, returning the panel to the same curvature it had before the damage occurred. The work is delicate and requires training to learn how to read the dent, apply the correct amount of force, and smooth the repair so that the damage disappears. When done correctly, PDR leaves no trace that the dent was ever there.

Paintless Dent Repair is used in a wide range of situations: door dings caused in parking lots, minor impact dents, small creases, and hail damage that covers multiple panels with dozens or even hundreds of dents. It is used by dealerships, collision centers, insurance companies, body shops, and individual customers. What makes PDR unique is that it preserves the factory finish, which is extremely important for vehicle value. A vehicle that retains its original paint holds a higher resale and trade-in value compared to one that has been repainted.

“The best repair is the one you can’t tell ever happened.”

Why Paintless Dent Repair Exists

Before PDR became widely known, dents were typically repaired using traditional bodywork. This involved sanding the surface, applying body filler, repainting, and blending color to match. While effective for severe damage, traditional bodywork has downsides. The repaint does not match the original factory paint perfectly, the process can be time-consuming, and the work is more expensive. Paintless Dent Repair solves these problems when the damage has not broken or cracked the paint. Because the original paint remains untouched, the vehicle looks as it did before the damage — not repaired, but simply unchanged.

This is why PDR is now the preferred repair method among:

-

Dealerships preparing cars for sale

-

Car owners concerned about value loss

-

Insurance companies managing hail claims

-

Body shops using PDR to avoid unnecessary repainting

PDR is the ideal solution for dents where the metal can still be reshaped, and the paint remains intact.

The Science Behind PDR

Metal has memory. When it is manufactured, it is shaped and formed under controlled pressure. A dent disrupts this memory, pushing the metal inward or stretching it. PDR works by reversing the deformation, guiding the metal back into its original curve. The paint flexes along with the metal during this process, which is why it is crucial that the paint is not cracked when the repair begins.

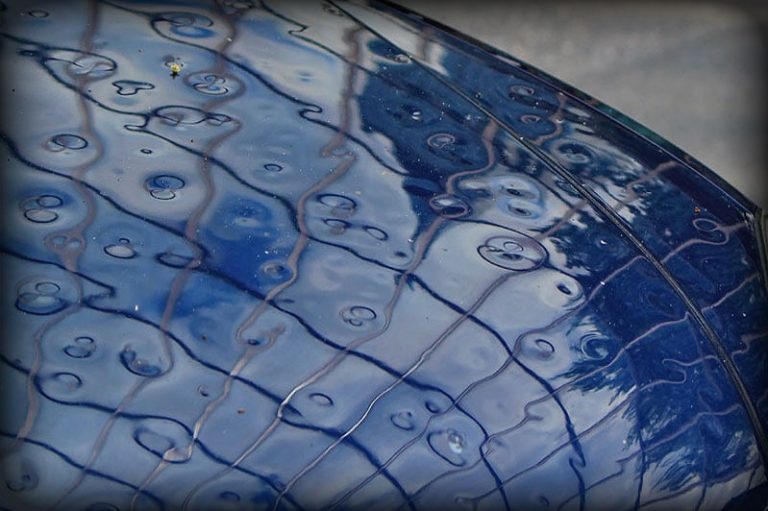

The technician reads the surface using reflection, often through a PDR light board that produces controlled lines. These lines distort where the dent exists, showing the exact shape, depth, and direction of tension. The reflection tells the technician where to push and how much.

PDR is not guesswork. It is precision-controlled pressure on metal.

How Paintless Dent Repair Works

While the process appears simple from the outside, it is detailed and requires significant training to perform correctly. The technician must be able to locate the backside of the dent, choose the correct tool, apply pressure with extreme control, and blend the surface to remove micro-highs and lows. The repair must be performed slowly to avoid over-correction or ripples.

Here is how PDR works, step by step:

-

The dent is identified and examined under proper lighting.

-

The technician gains access to the back of the dent by removing interior panels, reaching through existing factory openings, or using external glue pulling.

-

Using specially shaped rods, levers, and tools, the technician applies carefully measured pressure behind the dent.

-

The surface is massaged, not forced, back into shape.

-

High spots are gently tapped down to maintain a smooth and consistent reflection.

The goal is complete restoration — returning the panel to its original shape, finish, and natural curve.

The work is slow, controlled, and purposeful.

Tools Used in Paintless Dent Repair

PDR tools are designed to reach behind panels and apply precise pressure. They come in different lengths, shapes, and tip materials. The technician selects the right tool based on:

-

Panel location

-

Metal thickness

-

Dent shape and size

-

Available access points

Some tools push from behind. Others pull from the front when access is limited. The work also involves tap-down tools, which are used to smooth high spots and shape the panel back to uniform reflection. Lighting is essential, because the technician must be able to see subtle surface movement.

Skill in PDR is not about strength. It is about control.

When PDR Can Be Used

PDR is effective when:

-

The clear coat and paint are intact

-

The metal is not severely stretched

-

The dent has not created sharp paint fractures

-

The internal structure behind the dent allows access

This includes:

-

Hail damage

-

Parking lot door dings

-

Grocery cart impacts

-

Minor fender dents

-

Roof dents from debris

-

Soft creases

Severe damage where metal is torn or paint is cracked may require traditional repair — but even then, PDR can sometimes be used to minimize filler and paint work.

Why PDR Matters for Vehicle Value

Factory paint is the strongest, most durable paint a car will ever have. It is applied under controlled environmental and chemical conditions that cannot be replicated during repainting. Once a vehicle is repainted, even at high-quality shops, the finish is no longer original. This reduces collector value, trade-in value, and retail desirability. Paintless Dent Repair preserves the original finish, which means value is maintained — and often regained.

| Repair Method | Preserves Original Paint? | Time Required | Cost | Result Quality | Resale Value Impact |

|---|---|---|---|---|---|

| Paintless Dent Repair | Yes | Low to Medium | Medium to High Value | Factory Match | Maintains Value |

| Traditional Bodywork | No | Medium to High | High | Blended Paint Match | Reduces Value |

| Panel Replacement | No | High | Very High | New Panel Paint | Reduces Value |

PDR is the least invasive repair method and the most value-protective.

Why PDR Is a Learnable Skill

PDR is a skill that improves through consistent practice. It requires training, repetition, and guided correction. With instruction and hands-on work, beginners develop:

-

Tool control

-

Metal movement awareness

-

Surface reading technique

-

Light board interpretation

-

Confidence in dent approach and finish blending

Anyone willing to practice can learn PDR. It is a craft of patience and persistence.

Key Takeaways

Paintless Dent Repair restores dents without repainting, preserving factory finish and value.

PDR requires precision, training, and controlled technique — not force.

The process involves reshaping metal by applying guided pressure behind the dent.

It is the preferred method for retail customers, dealerships, and insurance repairs.

FAQs

Q: Can I learn PDR without prior automotive experience?

Yes. PDR is a hands-on skill taught through training and practice.

Q: Does PDR work on every dent?

It works when the paint is intact and the metal can be reshaped without cracking.

Q: How long does it take to become good at PDR?

Most students see real progress in weeks and continue improving with practice.

Conclusion

Paintless Dent Repair is one of the most valuable skills in the auto reconditioning industry because it preserves value, creates visible results, and rewards craftsmanship. If you want to learn PDR correctly, develop confidence with guidance, and begin building a real income skill you can use anywhere, call 800-304-3464. We’ll walk you through training options and help you choose the path that fits your goals.